Sub-surface Voiding

Voiding can occur for various reasons, including natural settlement, erosion, and construction issues. Natural voiding might be caused by the settlement of the ground, washout due to leaking water pipes, or the formation of sinkholes. Man-made voids might include basements, culverts, underground tanks, tunnels, pipes, and chimney flues. Detecting these voids early is crucial to maintaining the structural integrity of concrete structures.

Voiding in the sub-surface can cause failures of the overlying strata, especially under abnormally heavy loads. A void’s collapse beneath a carriageway can lead to structural damage and accidents. Voids beneath warehouse slabs or loading bays can cause slab deterioration and potential failure, particularly if subjected to heavy traffic by forklifts or lorries. Therefore, detecting and locating voids is highly desirable, enabling repairs before structural problems arise, thus improving safety and saving money.

Void Detection Using GPR

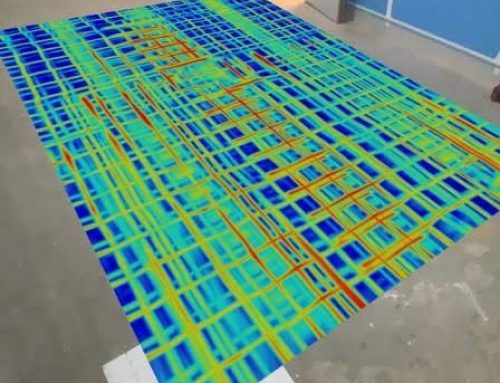

Using Ground Penetrating Radar (GPR) allows for the detection of potential hazards within concrete structures. GPR scans the ground on a regular orthogonal grid, identifying and plotting the extent of voids and other subsurface anomalies. This provides a comprehensive assessment of the concrete’s condition. Shallow voids can be detected effectively, and the survey is non-intrusive, cost-effective, and capable of covering large areas quickly.

GPR can be equipped with antennas of different central frequencies. Higher frequencies offer better resolution, while lower frequencies provide greater penetration depth at the cost of resolution. Thus, deeper voids need to be larger to be detected by GPR. Because GPR detects changes within the subsurface, it can identify both open and infilled voids, as long as the infill material’s properties differ significantly from the surrounding material.

Detection of Voids Within Concrete Structures

Voids within concrete can lead to structural weaknesses and potential failures. Early detection through GPR surveys enables timely repairs, minimising risks and costs. Voids under concrete slabs can eventually cause cracking and potential slab failure, making early detection essential to reduce risks and avoid expensive repairs. Settlement due to poorly compacted fill, erosion, burrowing rodents, decaying organic material, and even moisture loss from tree roots can create voids.

By scanning the concrete slab on a regular grid, GPR can detect voids below the slab and determine their extent. This information allows for appropriate remedial measures to be undertaken, ensuring the integrity of the concrete structure.

Detection of Voids in Stone Walls

Stone walls, especially in old structures like churches, can develop voids within their rubble core infill over time. Traditional methods of detecting these voids involve drilling into the wall and feeling for voids, which is slow and variable. GPR offers a much faster and potentially more reliable method of detecting voids. By scanning on a regular orthogonal grid, large wall areas can be scanned quickly, providing a detailed picture of voiding. This data can be used to plan effective remedial actions, such as pumping grout into the wall core to fill any voids.

Survey Deliverables

Results from our GPR surveys are typically presented in detailed reports and CAD drawings, showing the location and extent of detected hazards within concrete structures. This comprehensive documentation helps in planning and executing necessary repairs, ensuring structural safety and longevity.

Need More Information?

Contact us to learn more about our GPR concrete inspection services and how we can help ensure the safety and longevity of your structures. Our expertise in detecting sub-surface voiding can provide you with the insights needed to maintain and protect your concrete structures effectively.